DIN 440 Type R - Wood Construction Washers

This product guide contains the specification for metric timber construction washers (type R), standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 440.

The standard states a hardness class of 100 HV for these washers.

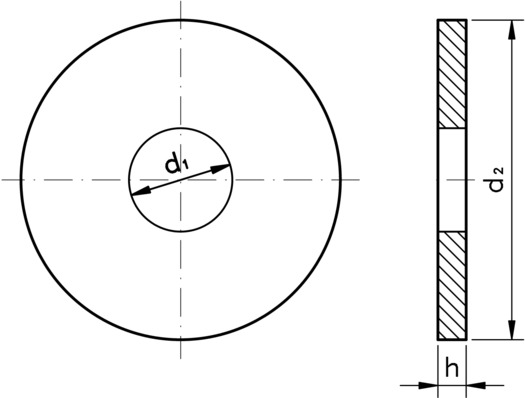

Figure 1: Timber Construction Washer to DIN 440 (Type R)

| Nominal Size | For Thread Size | Hole Diameter, d1 | Outside Diameter, d2 | Thickness, h | Approximate mass (7.85kg/dm3), per 1000 units, in kg | ||||

|---|---|---|---|---|---|---|---|---|---|

| min=nom | max | max=nom | min | nom | max | min | |||

| 5.5 | M5 | 5.5 | 5.8 | 18 | 16.9 | 2 | 2.3 | 1.7 | 3.62 |

| 6.6 | M6 | 6.6 | 6.96 | 22 | 20.7 | 2 | 2.3 | 1.7 | 5.43 |

| 9 | M8 | 9 | 9.36 | 28 | 26.7 | 3 | 3.6 | 2.4 | 13.0 |

| 11 | M10 | 11 | 11.43 | 34 | 32.4 | 3 | 3.6 | 2.4 | 19.1 |

| 13.5 | M12 | 13.5 | 13.96 | 44 | 42.4 | 4 | 4.6 | 3.4 | 43.3 |

| 15.5 | M14 | 15.5 | 15.93 | 50 | 48.4 | 4 | 4.6 | 3.4 | 55.7 |

| 17.5 | M16 | 17.5 | 18.2 | 56 | 54.1 | 5 | 6 | 4 | 87.2 |

| 22 | M20 | 22 | 22.84 | 72 | 70.1 | 6 | 7 | 5 | 174 |

| 24 | M22 | 24 | 24.84 | 80 | 78.1 | 6 | 7 | 5 | 215 |

| 26 | M24 | 26 | 26.84 | 85 | 82.8 | 6 | 7 | 5 | 242 |

| 30 | M27 | 30 | 30.84 | 98 | 95.8 | 6 | 7 | 5 | 322 |

| 33 | M30 | 33 | 34 | 105 | 102.8 | 6 | 7 | 5 | 368 |

| 36 | M33 | 36 | 37 | 112 | 109.8 | 6 | 7 | 5 | 416 |

| 39 | M36 | 39 | 40 | 125 | 122.5 | 8 | 9.2 | 6.8 | 695 |

| 42 | M39 | 42 | 43 | 140 | 137.5 | 8 | 9.2 | 6.8 | 881 |

| 45 | M42 | 45 | 46 | 150 | 147.5 | 8 | 9.2 | 6.8 | 1010 |

| 48 | M45 | 48 | 49 | 160 | 157.5 | 8 | 9.2 | 6.8 | 1150 |

| 52 | M48 | 52 | 53.2 | 170 | 167.5 | 10 | 11.2 | 8.8 | 1620 |

| 56 | M52 | 56 | 57.2 | 180 | 177.5 | 10 | 11.2 | 8.8 | 1800 |