DIN 435 - Square Taper Washers for I-Sections

This product guide contains the specification for metric sized square taper washers for I-section beams, standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 435.

I-sections are metal beams used in building construction, which are also known as I-beams or H-beams. I-section beams are available in parallel as well as tapered profiles.

This standard covers steel washers, the grade being at the manufacturer's discretion. The hardness is between 100-250 HV 10, with the 10 figure referring to a 10kg load.

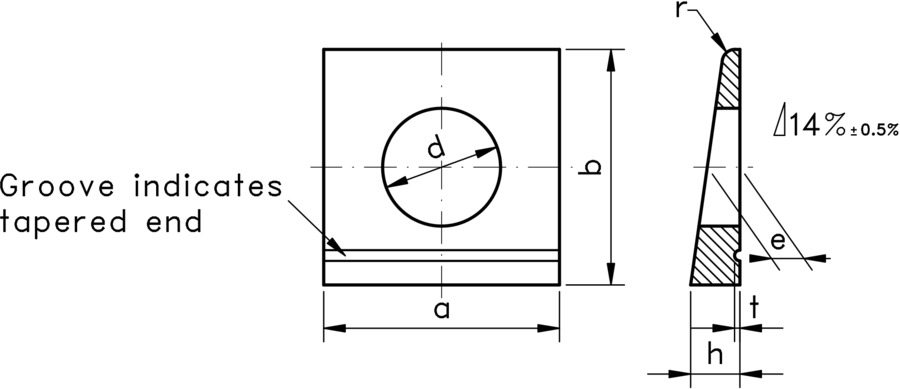

Figure 1: Square Taper Washer for I-Sections, to DIN 435

| Nominal Size | For Thread Size | d | a | b | e | h | r | t | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min=nom | max | nom | min | max | nom | min | max | nom | min | max | |||||

| 9 | M8 | 9 | 9.36 | 22 | 20 | 24 | 22 | 21.35 | 22.65 | 3.05 | 4.6 | 3.6 | 5.6 | 1.2 | 0.5 |

| 11 | M10 | 11 | 11.43 | 22 | 20 | 24 | 22 | 21.35 | 22.65 | 3.05 | 4.6 | 3.6 | 5.6 | 1.2 | 0.5 |

| 14 | M12 | 14 | 14.43 | 26 | 24 | 28 | 30 | 29.35 | 30.65 | 4.1 | 6.2 | 5 | 7.4 | 1.6 | 0.7 |

| 18 | M16 | 18 | 18.43 | 32 | 29.5 | 34.5 | 36 | 35.20 | 36.80 | 5 | 7.5 | 6.3 | 8.7 | 2 | 0.8 |

| 22 | M20 | 22 | 22.52 | 40 | 37.5 | 42.5 | 44 | 43.20 | 44.80 | 6.1 | 9.2 | 8 | 10.4 | 2.4 | 0.9 |

| 24 | M22 | 24 | 24.52 | 44 | 41.5 | 46.5 | 50 | 49.20 | 50.80 | 6.5 | 10 | 8.8 | 11.2 | 2.4 | 1 |

| 26 | M24 | 26 | 26.52 | 56 | 53 | 59 | 56 | 55.05 | 56.95 | 6.9 | 10.8 | 9.3 | 12.3 | 2.4 | 1 |

| 30 | M27 | 30 | 30.52 | 56 | 53 | 59 | 56 | 55.05 | 56.95 | 6.9 | 10.8 | 9.3 | 12.3 | 2.4 | 1 |