Westfield Fasteners Product Specification:

DIN 963 - Slotted Countersunk Head Screws

This product guide contains the specification for metric threaded slotted countersunk screws as available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 963.

A slot drive, countersunk headed screw, typically used in conjunction with a countersunk hole which provides a flush, snag free fit.

Scope of the DIN 963 standard.

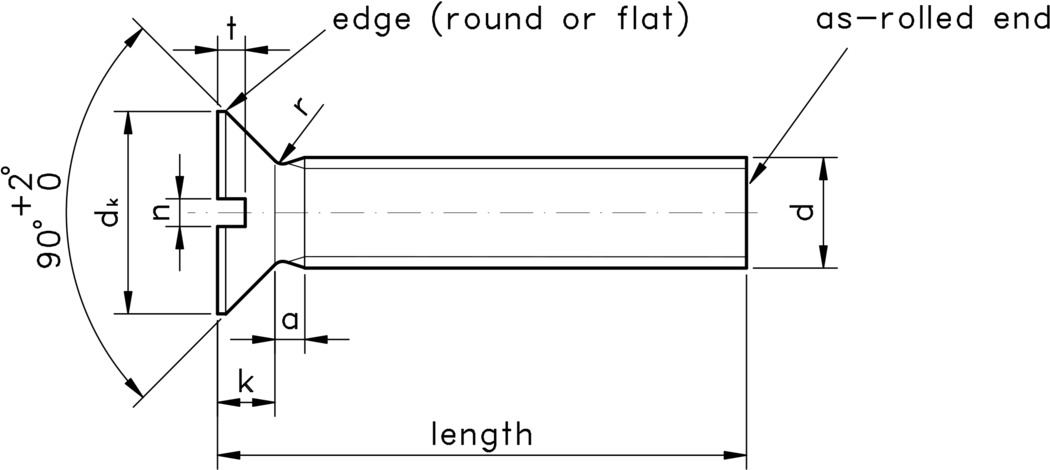

The DIN 963 standard specifies the tolerances and variation in form of slotted countersunk head machine screws, and covers metric thread diameters for sizes M1 up to and including M20. Table 1 below defines the overall dimensions and tolerances of this screw type, and should be used in conjunction with the diagram in figure 1. Table 2 defines the tolerance on the overall length. It should be noted that all lengths stated for countersunk screws are for the overall length, including the head. This is different from other types of screw that have heads designed to sit above the surface of the workpiece. In this case lengths quoted are for the shank length under, but not including the head.These are generally fully threaded. The ISO standard does include details for the part threaded version, which we have not covered here.

DIN 963 covers steel classes 4.8, 5.8 and high tensile 8.8, together with A2 and A4 stainless steel, and copper and zinc alloy (brass).

Although the DIN 963 standard has now been superceded by ISO 2009, off the shelf parts are generally still manufactured to the older specification. The ISO standard specifies some revised dimensions and tolerances.