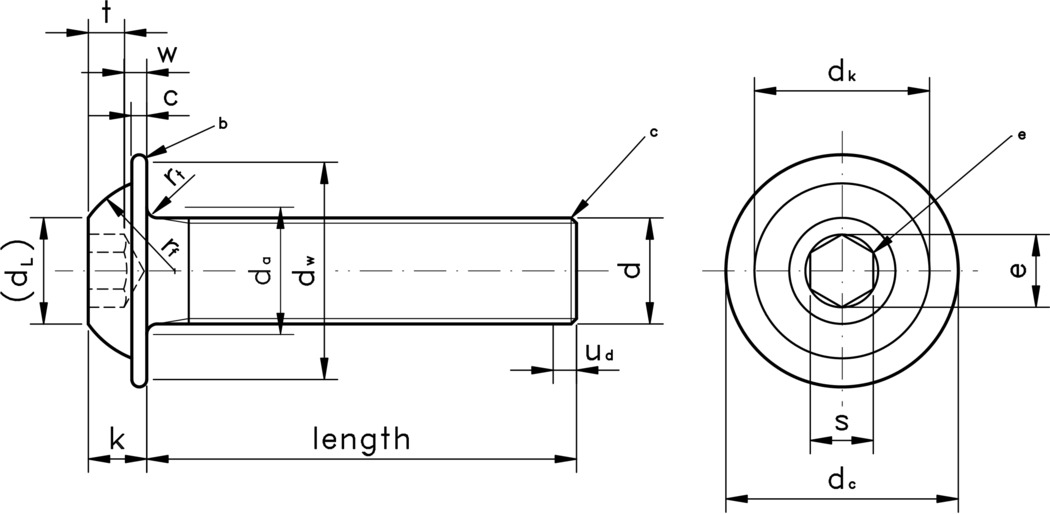

ISO 7380 part 2 - Hexagonal Socket Button Head Screws with Flange

This product guide contains the specification for metric threaded socket head button screws with flange as available from Westfield Fasteners. The basis of this specification is the ISO standard ISO 7380 part 2, but this specification may include information on sizes and materials that are not covered by the ISO standard but are available.

Table 1 below defines the overall dimensions and tolerances of this screw type. Table 2 defines the tolerances on the shank length, whilst table 3 shows the reduced minimum ultimate tensile loads for this product. The information in table 3 is presented here because due to their head design socket button screws are considered to have reduced loadability over other screw types, as defined in ISO 898 and ISO 3506.

ISO 7380 part 2 covers steel grades 8.8 and 10.9. Stainless steel variants are not mentioned explicitly in this version of the standard, but conform to the dimensions stated.

ISO 7380 part 1 is a seperate standard that covers hexagon socket button screws without the flange.